Unknown Facts About Injection Mold

Wiki Article

The 2-Minute Rule for Injection Mold

Table of ContentsIndicators on Injection Mold You Need To KnowThe Best Strategy To Use For Injection MoldSome Ideas on Injection Mold You Need To KnowAn Unbiased View of Injection Mold5 Easy Facts About Injection Mold ExplainedThe Of Injection Mold

For the mold producer and the part developer, the precise information from the simulation make their work much simpler. For computer simulations to work and supply reasonable outcomes, the computers first require a whole lot of input.The exact same can take place if the model to be calculated has actually been streamlined a lot on the computer system that it does not mirror reality. Extremely specialist shot molding simulation programs therefore contain extensive databases derived from plenty of measurements. Most of all, this includes current material information, which have a substantial influence on the outcomes of the simulation.

Service-strong software manufacturers therefore focus on user-oriented individual interfaces and also supply easy-to-understand, user-specific and also interactive training programs. > Advantages & Disadvantages of Reaction Shot Molding by Rimnetics, uploaded on Monday, January 24, 2022 Reaction injection molding (RIM) has been made use of to develop parts for a large array of various industriescomplex medical devices to building and construction tools. As a lot of product designers know, the production process you select will substantially affect the expense, looks, and outcome of your last item.

In doing so, you can best identify which process will certainly finest match the particular demands of your task. Listed below, we highlight the notable benefits and also drawbacks of reaction injection molding to assist maximize your decision-making process.

The mix of polyol as well as isocyanate creates a fluid with an uniformity similar to that of electric motor oil, which allows the blend to easily stream right into every nook and cranny of even one of the most complex molds. Hence, no severe temperatures or pressures are essential to melt and develop the plastic.

The 7-Minute Rule for Injection Mold

The low pressures and temperature levels associated with the RIM process can assist in the encapsulation of a vast range of components, such as antennas, circuit boards, magnets, batteries, steel poles, and threaded inserts. Encapsulation can offer various advantages, such as boosted protection for more delicate components, burglary prevention, as well as minimized parting lines.

Some Known Details About Injection Mold

RIM is much a lot more cost-effective when it comes to creating larger partsespecially in smaller production quantities. In enhancement to creating majorities, RIM is additionally well-suited for developing and building get rid of intricate geometries. Reaction injection molding differentiates itself via the high level of layout liberty it provides. RIM can create parts with varying wall surface densities, curves, and also encapsulated parts, among various other in-demand functions.For this reason, RIM is regularly hired to create components for medical gadgets as well as laboratory devices. The capacity to reduce the number of parting lines on a part is an additional benefit supplied by the reaction injection molding process. As we formerly mentioned, RIM allows makers to envelop things directly into a part as well as create bigger, complex parts in an effective as well as affordable way.

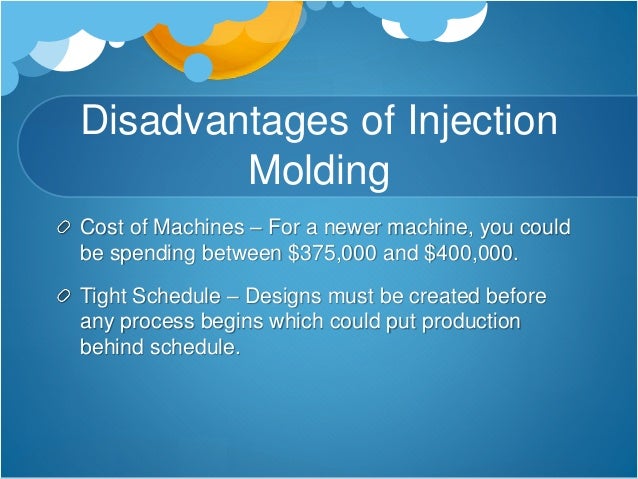

Reaction injection molding also has a couple of disadvantages. Just like any type of manufacturing process, there are particular applications for which response injection molding might not be proper. read review Its drawbacks are limited, but it's essential to identify when reaction injection molding may not match your details task. RIM typically isn't well-matched for parts needing larger manufacturing quantities.

4 Easy Facts About Injection Mold Shown

If your yearly production volume drops within this array, the substantially lower tooling cost of edge will substantially balance out production expenses. However, given that RIM likewise needs extra finishing and post-molding work, it typically has a slightly higher private component rate than injection molding. Hence, when you require to produce components in incredibly high quantities, the greater private component prices will inevitably exceed the expense savings offered by a much less expensive device.We wish this guide on the major advantages as well as disadvantages of reaction injection molding assists you establish whether RIM is a suitable method for your production project. If you believe your job could gain from useful link the response injection molding process, Rimnetics can aid. Rimnetics is The United States and copyright's leading response injection molding business for enclosures, cosmetics real estate, architectural parts, encapsulation, and also over-molding.

Discover a more tips here lot more concerning the premium edge services that Rimnetics gives; call us today.

Some Of Injection Mold

To aid, we have actually extremely simply outlined the benefits and also downsides to take into consideration. Please be mindful, nonetheless, that the adhering to standards apply to what we would think about to be standard shot moulding (quantities of 100,000+) and might appear in the beginning glance to be fairly expensive if you are wanting to develop an item with numbers out of this norm.In enhancement, we are professionals in making injection moulding much a lot more set you back reliable for a lot reduced quantities of components than is extra typically expected. The result is a mould device that shows the demand and opens up an amazing alternative to create high quality, yet reduced volume components.

Report this wiki page